Laser IC Opener

Outline

NSC IC Opener PL201 Series is equipped with fiber laser, and it has achieved a lower cost and longer lifetime as compared to a conventional solid-state laser. PL201-20 and PL221 are also capable of cross-sectioning.

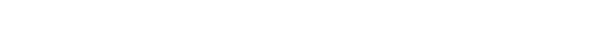

Preparation for Acid or Plasma Decapsulation

By removing epoxy molding compound by laser, acid consumption and decap time with acid or plasma can be greatly reduced.

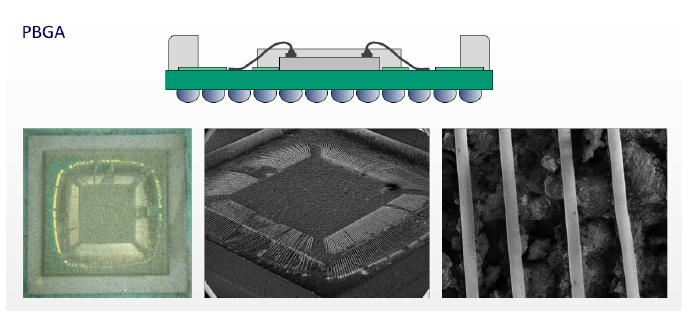

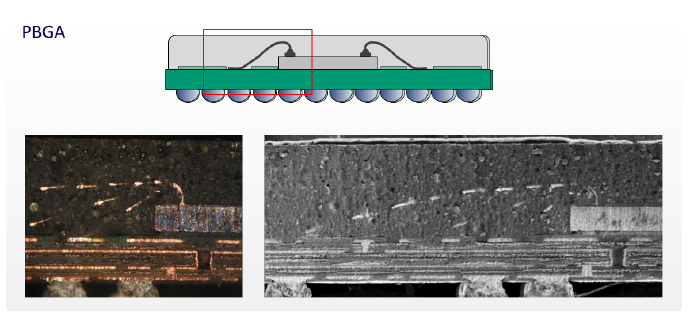

Cross Section

PL201-20, PL221 are equipped with 20W fiber laser, and capable of cross-sectioning packages and cutting out IC on PCB.

PL221 with larger chamber

Large samples like PCB can be placed on the 397x170mm stage.

Advantages of Fiber Laser

Lower Cost

System price is reduced due to a cost reduction on the laser unit.

Significant improvement of decapsulation speed

Because high power laser can be used with less damage on bonding wires, decapsulation speed was greatly improved.

Safe and Clean Design

Class 1 Laser product.

High resolution real time imaging during decap process.

Signal Tower to visually confirm the operation status.

Key Switch / Laser Safety Interlock

Key switch to prevent unauthorized use. Safety interlock to disable the laser when the door is open. System prohibits the door from opening during operation.

Easy Operation

Operation Interface

User-friendly software by simply selecting pre-set laser condition. User can set the decap area by mouse drag or numerical value input. X-ray, C-Sam, Optical, Schematic image overlay for easy positioning. Adjustable image brightness.

Clear images

High resolution 5 Mega-pixel camera with 25mm lens (Field of View: 45x35mm) for clear images.

Option: 12mm (Field of View: 90x70mm), 16mm (64x50mm) or 35mm lens (29x20mm)

Option: 12mm (Field of View: 90x70mm), 16mm (64x50mm) or 35mm lens (29x20mm)

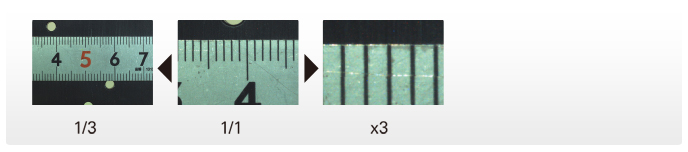

Digital Zoom Capability

Accurate decap area setting with 2x, 3x zoom in and 1/2, 1/3 zoom out functions. Capable of working on packages smaller than 1mm x 1mm.

Repeatable Recipe

Recipe can be stored and repeatedly used. Stage height is automatically adjusted after every scan to maintain the same focal length.

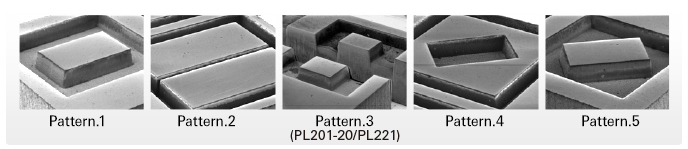

Process Patterns