MULTI SHINER

Summary / Feature

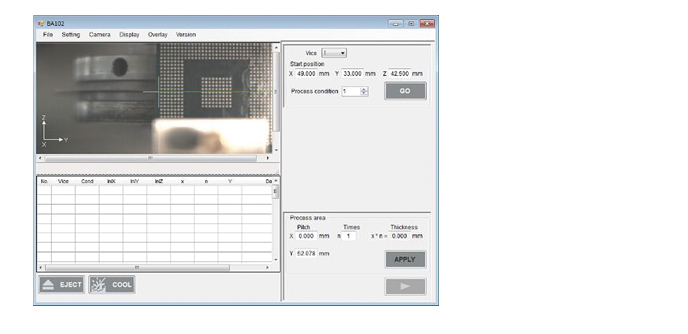

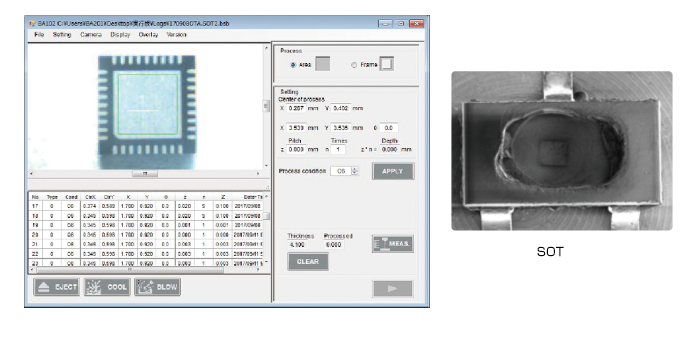

- 2 cameras are attached to observe samples from different angles. Process area can be easily defined on the sample image displayed on PC screen with a mouse.

• Windows interface

• Overlay function - Various vices are attached to fix samples on the stage.

- Air-Chuck enables easy replacement of different operation tools.

- Safety features: Earth leakage breaker, Liquid leakage detection, Door interlock, and Signal tower.

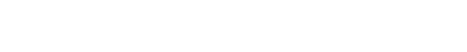

- 3 capabilities of BA102

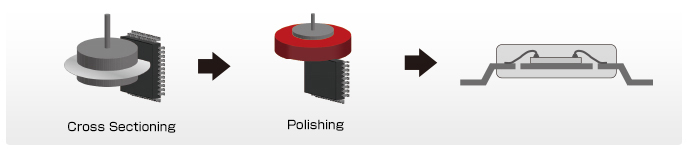

1. Cross Sectioning / Polishing

2. Surface Grinding / Polishing

3. Cutting out

1. Cross Sectioning / Polishing

Diamond blade is used for cross sectioning. Polishing blade and diamond liquid are used for polishing a cross-sectioned surface.

Process conditions can be selected from the menu on the PC. Process area can be specified by entering numerical values or drawing a box on the screen with a mouse.

Total cycle-time is greatly reduced as it is no longer required to perform sample-preparation (Encapsulate the sample in plastic or resin for preparation).

Easy and accurate sample re-loading after frequent removal for observations.

Water-soluble, Rust-proof coolant is supplied to the sample to support high-speed and low-temp processing.

Maximum cross section length of 10cm.

Grind stone is attached for maintaining the quality of the cutting blade.

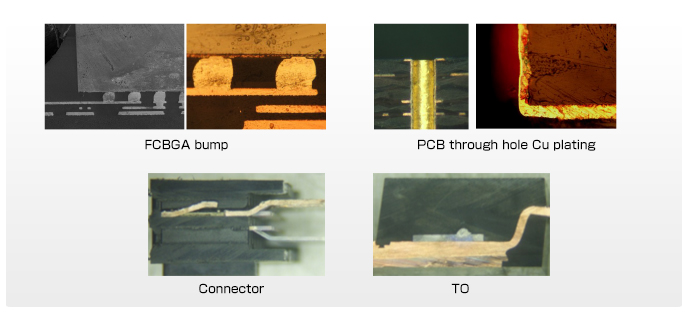

Capable of working on variety of materials ranging from metal to plastic for observation of bump metal alloy layers, PCB through hole Cu plating, and connector check on a cross-sectioned surface.

Easy and accurate sample re-loading after frequent removal for observations.

Water-soluble, Rust-proof coolant is supplied to the sample to support high-speed and low-temp processing.

Maximum cross section length of 10cm.

Grind stone is attached for maintaining the quality of the cutting blade.

Capable of working on variety of materials ranging from metal to plastic for observation of bump metal alloy layers, PCB through hole Cu plating, and connector check on a cross-sectioned surface.

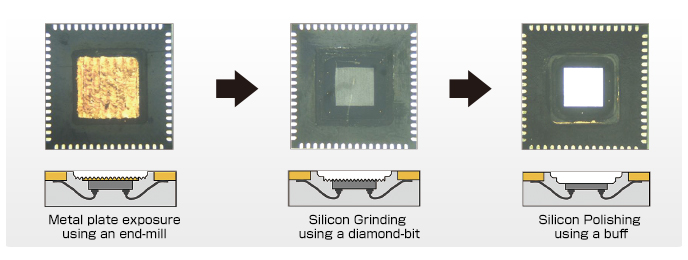

2. Surface Grinding / Polishing

End-mill is used for grinding of molding compound and metal. Diamond bit is used for grinding Silicon and diamond paste is used for backside polishing. Suitable for OBIRCH, Emission, and LIT analysis as the system allows backside processing without damaging leads.

Process conditions can be selected from the menu on the PC. Process area can be specified by entering numerical values or drawing a box on the screen with a mouse. Process area on small samples can be easily and precisely defined.

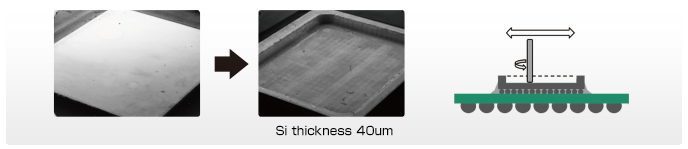

Laser distance measurement unit (Resolution: 1um) measures the height and calculates the removed amount of material during each process. System is capable of thinning Silicon to less than 50um thickness.

Suitable for observation of wiring layers of PCB.

Suitable for thinning thick samples to right above bonding wires before wet-etch process, thus reducing wet-etch cycle-time and acid consumption.

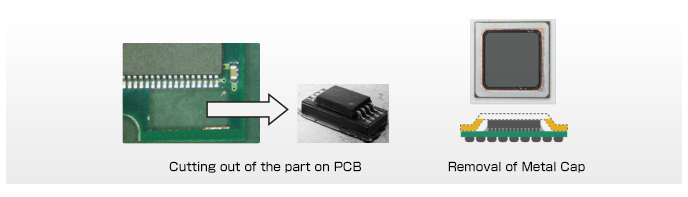

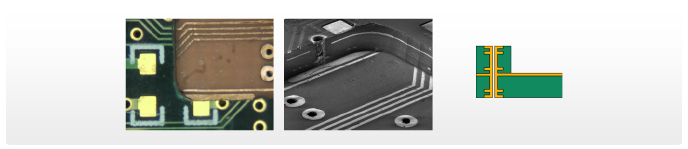

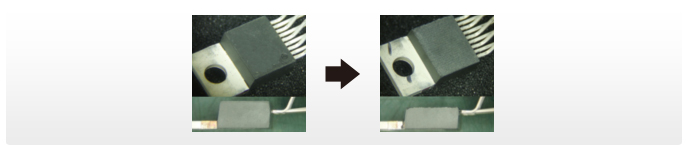

3. Cutting out

End mill is capable of cutting out sample from PCBA.

Suitable for extracting out any part mounted on PCB, removal of the metal cap, and taking the bare chip out from packages.

Suitable for extracting out any part mounted on PCB, removal of the metal cap, and taking the bare chip out from packages.