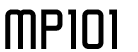

Atmospheric Plasma Needle Decap System

Outline

MP101 is a IC package decapsulation system which decomposes molding compound utilizing O2 plasma generated by atmospheric microwave plasma needle.

Features

- Chip can be exposed in several hours. (Etch time varies depending on the type of molding compound and device structure)

- O2 plasma decap is suitable for functionality analysis as it has less damage to lower passivation layers.

- System is very compact without a vacuum pump as O2 plasma is generated in an atmospheric condition

- Eco-friendly system which utilizes Argon and Oxygen only for plasma generation, and water for cleaning. Acid use and disposal is no longer required.

- Silica filler removal process (Ultrasonic cleaning & Drying) is fully automated.

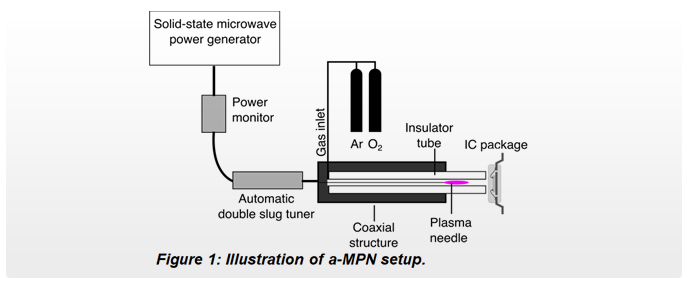

MP101 Principle

Gas mixture of Ar and O2 is fed into coaxial structure, and plasma is generated forming thin plasma needle at the tip of central conductor. Generated plasma is applied to IC package surface, and molding compound is decomposed to CO2 and H2O etc.

CxHyOz + O* › CO2 + CO + H2O O* : O2 Plasma

CxHyOz + O* › CO2 + CO + H2O O* : O2 Plasma

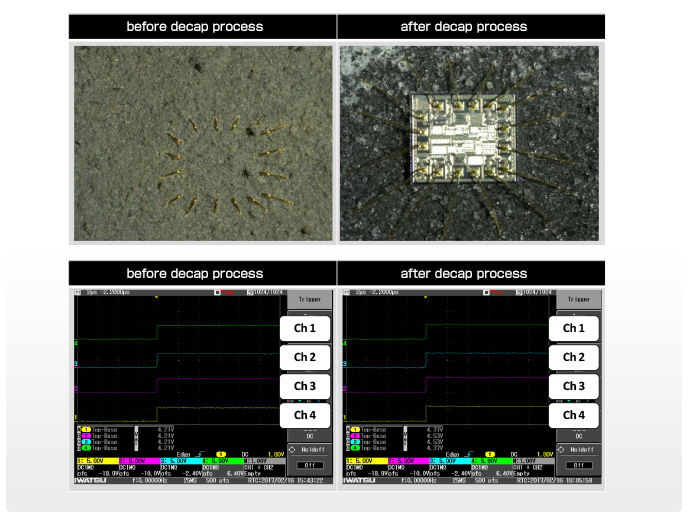

Decap Result

Laser system was used to reduce the amount of molding compound, and then O2 plasma was supplied to the surface of the sample.

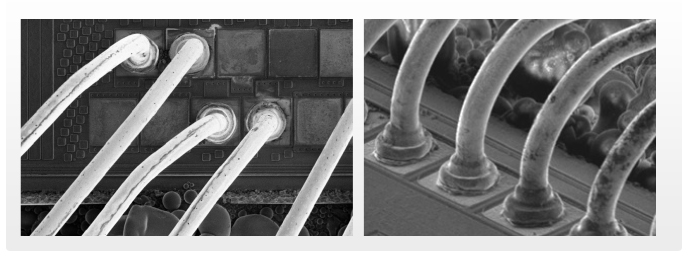

Observation of Cu bonding wires

No wire thinning is observed

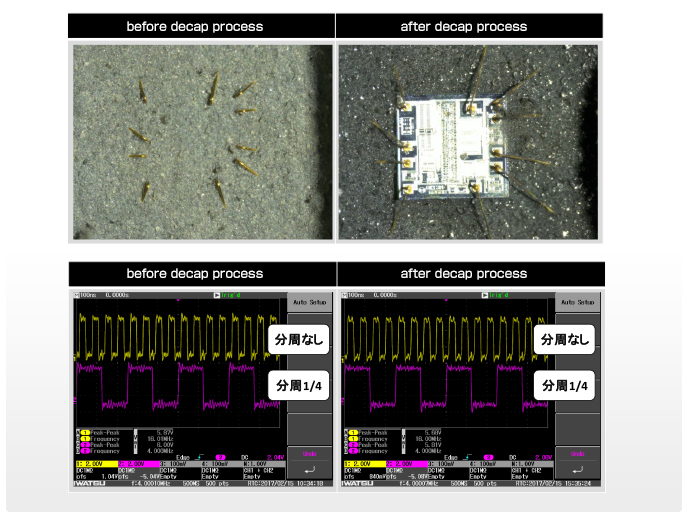

Characteristic Change

Samples decapped by MP101 were tested for characteristic change using an oscilloscope. Result show, there was no characteristic change before and after decap process.

8 pin DIP Au bonding wired sample CMOS Crystal Oscillator Check (16MHz)

No characteristic change was confirmed

16 pin DIPAu bonding wired sampleS-R latch circuits check

No characteristic change was confirmed